Products: Abaqus/Standard Abaqus/CAE

Benefits: Contact stress error indicator output helps convey a sense of contact stress accuracy.

Description: Contact pressures and contact shear stresses are often of key interest in engineering systems, so it is often important to have confidence in the accuracy of these results. The surface-to-surface contact formulation facilitates obtaining good estimates of contact stresses, but accuracy relies on adequate mesh refinement and other modeling choices. Highly localized contact stress concentrations are quite common, which may call for local mesh refinement to accurately predict the maximum contact pressure. In some cases the problem posed may have a contact stress singularity where a corner of one surface interacts with a smooth portion of another surface, yet a finite element analysis will predict finite stresses regardless of the level of mesh refinement.

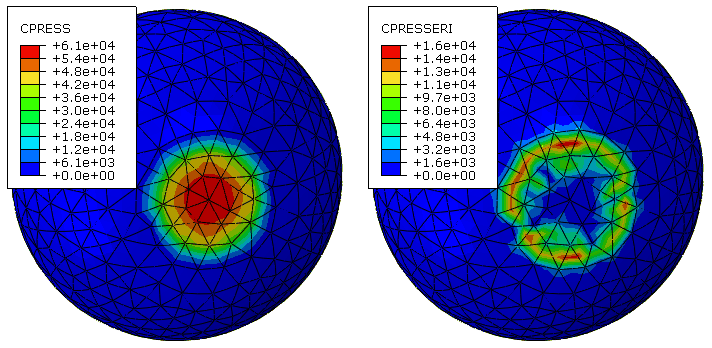

You can request output variable CSTRESSERI to generate contact pressure and contact shear stress error indicators, CPRESSERI and CSHEARERI. These error indicator fields provide estimates of error in the corresponding “base solution” output variable fields CPRESS and CSHEAR, respectively. These error indicators have units of stress (as with pre-existing error indicators, they are not normalized). Plots of CPRESS and CPRESSERI for contact between two elastic spheres modeled with quadratic tetrahedral elements (element type C3D10) and surface-to-surface contact are shown in Figure 13–16. These plots suggest that the contact pressure solution is quite accurate in the interior of the active contact footprint (where the maximum contact pressure occurs) and less accurate near edges of the contact footprint (where relatively large stress gradients occur and the contact pressure is significantly less than the maximum value). If the maximum contact pressure is of primary interest, this level of mesh refinement may be adequate for the loading considered.

Figure 13–16 Contour plots of CPRESS and CPRESSERI for contact between a deformable sphere and a rigid plate.

You should not assume that a sum (or other combination) of a base solution variable and the corresponding error indicator provides a conservative estimate of the true solution. An error indicator tends to give a crude, non-conservative approximation of the deviation from the exact solution if the mesh is coarse relative to local solution variations or the exact solution to the problem posed is singular. The following qualitative interpretations of error indicator results exceeding approximately 10% of base solution results are often appropriate:

“Significant potential for solution inaccuracy exists in this region.”

“The mesh may be too coarse to give a good estimate of solution error in this region.”

“Perhaps there is really a stress singularity at this corner.”

Local mesh refinement (in the original model or through submodeling).

Switching to the surface-to-surface contact formulation and activating surface geometry adjustments where appropriate for curved surfaces.

Switching to second-order elements in the contact region.

Rounding sharp corners to avoid stress singularities.

Additional insight on the accuracy of contact stress predictions can be gained through comparison to stresses in elements underlying contact surfaces. Significant deviation between contact stresses and corresponding underlying element stress components is another indication of potential inaccuracy.

Unlike other error indicators, contact stress error indicators cannot be used to control adaptive remeshing.

Step module: Field output request editor: Output Variables: Error indicators: CSTRESSERI